Elkonit Copper Tungsten

Elkonite is the registered trade mark of CMW used to identify a group of metal compositions whose elements consist basically of the refractory metals tungsten, molybdenum and tungsten carbide combined with copper. Combinations of these elements produce dense, hard metals of superior wear resistance and strength at elevated temperatures, coupled with good thermal and electrical conductivity. The mechanical and physical properties of the CMW Elkonite materials make them particularly suitable as the die inserts and facings for volume projection welding, flash and butt welding, electrical upsetting and electroforming applications.

Elkonite copper tungsten is also used successfully as facing on spot welding electrodes where heat balance or mechanical wear resistance are required. The initial premium cost of Elkonite copper tungsten is offset by lower production cost per weld due to long die life and less electrode dressing time. The high stability of Elkonite copper tungsten insures uniform heating and prevents misalignment, resulting in a higher quality weld.

Elkonite Copper Tungsten Main Properties

| Group |

Grade |

Composition(%wt) |

Class # |

hardness |

conductivity |

|

Elkonite10055 |

1W3 |

55W,45Cu |

10 |

70HRB |

49%IACS |

|

Elkonite10068 |

3W3 |

68W,32Cu |

|

83HRB |

42%IACS |

|

Elkonite10070 |

5W3 |

70W,30Cu |

11 |

88HRB |

42%IACS |

|

Elkonite10075 |

10W3 |

75W,25Cu |

|

92HRB |

38%IACS |

|

Elkonite10080 |

30W3 |

80W,20Cu |

12 |

98HRB |

34%IACS |

|

Elkonite10250 |

TC5 |

50WC,50Cu |

|

94HRB |

45%IACS |

|

Elkonite10256 |

TC10 |

56WC,44Cu |

|

100HRB |

42%IACS |

|

Elkonite10270 |

TC20 |

70WC,30Cu |

|

37HRC |

30%IACS |

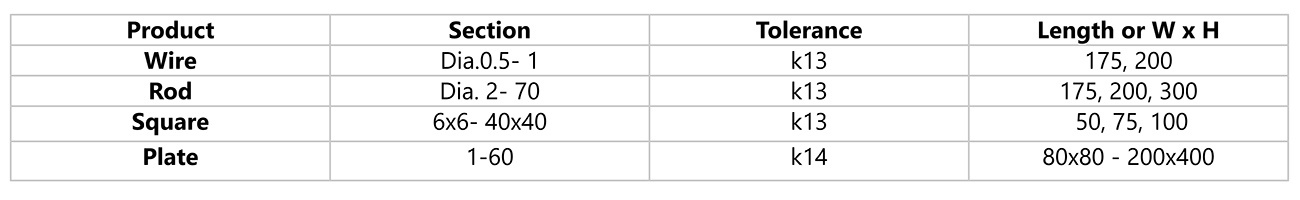

Copper Tungsten Round and Square Bar

Elkonite Copper Tungsten Generally Uses

RWMA Class 10

Elkonite 1W3 , Elkonite 3W3 , And Elkonite 5W3

Elkonite® 1W3 and Elkonite® 3W3 Tungsten-Copper alloys are generally used for flash and butt welding die inserts where higher electrical and thermal conductivity is necessary and where a degree of malleability is desirable. These materials are also used (as a radius faced electrode) for spot welding low conductivity ferrous metals such as stainless steel.

Elkonite® 5W3 Tungsten-Copper and Elkonite® TC5 Tungsten Carbide-Copper alloys are normally used for light duty projection welding dies where welding pressured are not extreme.

RWMA Class 11

Elkonite 10W3

Elkonite® 10W3 Tungsten Copper (75W / 25Cu) is used for electrode and die inserts in most flash and butt welding dies and for projection welding dies where welding pressures and moderate. Most nut & stud welding applications use this alloy brazed on the electrode face. It is also used for light electrical upsetting, electroforging dies and seam welder bushing inserts.

RWMA Class 12

Elkonite 30W3 & Elkonite TC10

Elkonite® 30W3 Tungsten-Copper and Elkonite® TC10 Tungsten Carbide-Copper alloys are recommended for volume projection welding dies where the pressures involved are relatively high. Electrical upsetting of non-ferrous metals and low carbon steel is usually accomplished by the use of such Elkonite® materials as die facings. Cross-wire welding of large diameter wire and rod is accomplished with such Elkonite® materials.

Elkonite 3W53 & Elkonite 10W53

Elkonite® 3W53 and Elkonite® 10W53 are heat treatable grades of Elkonite® Tungsten-Copper materials supplied in the fully heat treated condition. If silver brazed to a die backing, such Elkonite® materials should be heat treated after brazing. These harder grades are used primarily for electroforging and electrical upsetting dies, where temperatures and pressures are comparatively high.

Elkonite TC20 & Elkonite TC53

Elkonite® TC20 and Elkonite® TC53 are Tungsten Carbide-Copper materials and are extremely hard and wear resistance. Elkonite® TC20 material, while somewhat difficult to machine, may be machined using carbide tipped tools. Elkonite® TC53 material is a heat treatable grade of such high hardness that machining operations are impractical and the material must be ground. Such Elkonite® materials are customarily used for special applications of electrical upsetting and electroforging.

RWMA Class 13

Elkon 100W

ELKON 100W (Pure Tungsten) is extremely hard and its ductility is relatively low. It cannot be machined but may be ground to the required shape. It does not alloy appreciably with nonferrous materials and is used for cross-wire welding of metals such as copper and brass. It is also for electroblazing electrode material and for some electrical upsetting operations.

RWMA Class 14

Elkon 100M

ELKON 100M (Pure Molybdenum) is used principally for electroblazing electrode material and for cross-wire welding of nonferrous metals. It is not as hard as Elkon 100W material and may be machined or drilled to fit the parts to be joined. A typical application of this material, as an electrode, is the welding or brazing of braided or solid copper conductors to ferrous or nonferrous terminals, lugs, or fittings.